Business Focus

-

Contract manufacturer specialising in the manufacture of injection moulded plastic parts

-

Takatronics specialises in the manufacturing of plastic components. The company also provides other ancillary services such as silk-screen printing, hot-stamping, assembly and spray painting

-

Takatronics manufactures injection moulded plastic part by employing moulds that is fabricated by third parties for the production of the relevant plastic components. An injection moulded plastic part is one of many plastic components that form for example, an electronic product and is produced by plastic resins via an injection moulding process. The moulded plastic parts could be further categorised as (i) a component part or (ii) an assembly of plastic parts assembled into a sub-assembly product

-

Takatronics’ flexible manufacturing system enables it to manufacture a variety of plastic components of various products such as printers’ parts, telephone parts, auto gate parts, MP3 players, airbag system, earplugs and high heels amongst others

-

The plastic injections moulds used by Takatronics for its plastic injection moulding process are fabricated by third parties. Such moulds must be specifically engineered and fabricated with cavities to shape the plastic components in accordance with customers’ desired design, features and specifications. However, Takatronics assists in providing advise on the design of the mould to be used in the injection moulding process

-

The principal market of Takatronics is in Malaysia. Its customers comprise mainly producers of branded products (or their contract manufacturers). Takatronic’s industry sector experience ranges from electronics and electrical, automotive and consumer goods.

-

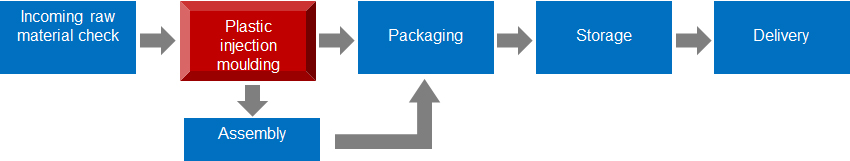

The following flowchart illustrates Takatronics’ typical injection moulding processes once the mould has been approved and accepted by the customer and is ready for use:

Plastic injection moulding is the most commonly used process to mass produce plastic components with great accuracy. Plastic resin raw material in the form of granules is fed into a heated barrel until they are molten resin and injected under pressure to fill the mould cavities. The result is that the resin is exactly moulded to the shape of the cavity. Once the plastic moulded parts cool to a hardened state, the injection mould opens releasing the injection moulded part. The whole injection moulding process then repeats. Each cycle of an injection moulding process may take approximately 30 to 55 seconds. Moulded parts will either be packaged for storage and/or delivery, or may be required for further assembly before storage and/or delivery.